KD3Z Gen6

Incredibly Fast Fabrication

The KD3Z is a full computer-controlled CNC process for cutting of Kingspan KoolDuct. The KD3Z process facilitates the design, fabrication and assembly of ductwork and fittings.

Previously, KoolDuct was laid-out with traditional measuring tools and duct work was cut from raw panels with knifes...but not anymore. Users design the job in the supplied software, able to preview the output before ever making a cut.

With KoolDuct set on the KD3Z table, the program is run, and the operator is free to work while the KD3Z cuts the raw material.

Not only does it save time...but it saves money.

Technology At Work For You

- Swivel PLC computer and PLC with optional touch screen

- Virtually indestructible Keyboard

- Robust 3"x3" extruded aluminum frame

- Industrial linear bearing and precision bearing rail

- Long life spoil board and superior material hold-down design feature

- A vast library of fittings and ductwork that allow you to make anything you need

- Reduces fabrication time from hours to minutes with repeatable accuracy

Dust Collection Systems

Keep your working environment clean with attached dust collection output ready to be connected to properly sized dust collectors. 5 hp output (32 amp)

User Interface

Easily navigate fabrication commands to operate all auxiliary equipment using included keyboard or with touch screen.

Open Bed Design

This provides unobstructed access to the machine bed, making it much easier to load and unload material. This proprietary machine bed has no spoil boards to surface and replace.

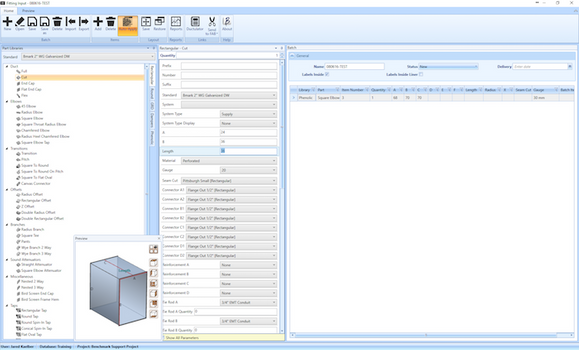

Benchmark Input Fitting Software

We give you a complete library of fittings and ductwork. Software accepts a variety of .DXF for any customized fitting needs.

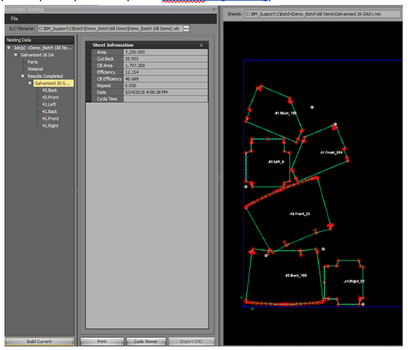

Profab Nesting Software

Powerful nesting software that helps arrange cuts for a higher yield per board.

Contractor Friendly Design

The KD3Z has been designed by contractors for use by contractors. The machine was engineered solely for the use of KoolDuct and insulated foam panels. The KD3Z process meets the contractor's need to be competitively in today's "green" marketplace.

With the KD3Z supplying the layout, finish work does not require your highly experienced workers. Ductwork also assembles faster and is better dimensionally due to the KD3Z's Cutting Precision.

It even preserves the end of the board, allowing fittings to remain intact on the flat panel for shipment to the field.

KD3Z Product Specifications

- LENGTH 193"

- WIDTH 62"

- HEIGHT 80"

- WEIGHT 2000 lbs

- Drive Motors 4 Motors, 3 Axis, CNC driven

- Warranty 1 year on parts due to failure or workmanship